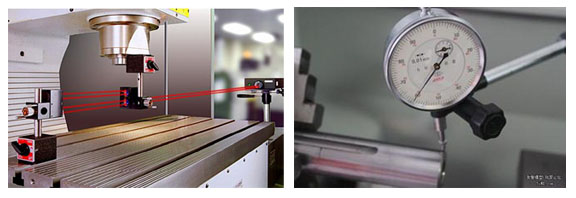

How to detect the accuracy of CNC cutting machine?

1. Using the machine to processing a wood board, measure whether the opposite corners of the plate are the same, whether the size of the opposite side is consistent, and whether the edge distance of the measuring hole is consistent.

2. The double-sided processing of the middle plate of the cabinet, check the positioning accuracy of the flap processing. In general, single-sided processing does not have strict requirements on positioning accuracy, and the positioning cylinder mainly affects the processing accuracy of flaps. Punch the board, open grooves on both sides, and observe whether the holes are transparent and whether there are traces of seams. Measure the sides of the hole and groove.

3. Accuracy of secondary processing. If there is edge trimming during processing, it depends on the adsorption capacity of the countertop to see if there will be no running board. In addition, small plate processing accuracy can also be measured.

Using the above three methods, the machining accuracy of the cutting machine can be quickly detected. The CNC cutting machine can effectively improve the processing efficiency, reduce the labor load, and save the production cost. The machine should not be limited to the price. The cutting machine should be processed every day. If the machine breaks down, it will affect the construction period and cause damage to the plate, which will seriously affect the customer's production progress. Therefore, the long-term stability, precision, configuration and machine details of the CNC cutting machine Very important.

中文

中文 English

English